History of Forging: From Humble Beginnings to a Modern Marvel

The Origins of Forging

The forging process first developed thousands of years ago, around 4000 to 7000 B.C., in the Middle East and quickly spread throughout Europe and Asia. By discovering fire, humankind soon learned that certain metals such as gold, silver, and copper could be heated at high temperatures and formed into various simple shapes. In the beginning, to forge a shape, small rocks, and eventually small hand hammers, would be used to hit the hot metal against a giant rock. As one could imagine, this primitive method would often lead to structurally compromised parts, resulting in uneven thicknesses and rough finishes in the final product. As humans learned more about forging, the process became more sophisticated. Metallurgy first came into practice with the creation of bronze, a sturdy alloy made up of copper and tin. Bronze quickly became the preferred metal of choice to forge, and for centuries, man began forging small hand tools and weaponry. This eventually caused a shortage in tin, which, unlike other metals, the origins of tin was not known at the time. Iron became the next metal of choice to forge, as it was more widely available. Forging evolved from small open fires to charcoal fire pits with bellows used to increase the temperature of the fire. In Asia, small chimney-like forging huts made of heat-resistant dirt and clay with an opening at the bottom were used and could be found throughout Asian countries. By the 13th century, waterpower had replaced bellows as a more efficient way to increase the heat in fire pits for forging. Over the centuries, forged parts and metals became more commonplace in general society. But the forging process wouldn’t experience significant changes until the 19th century.

Forging in the 19th century

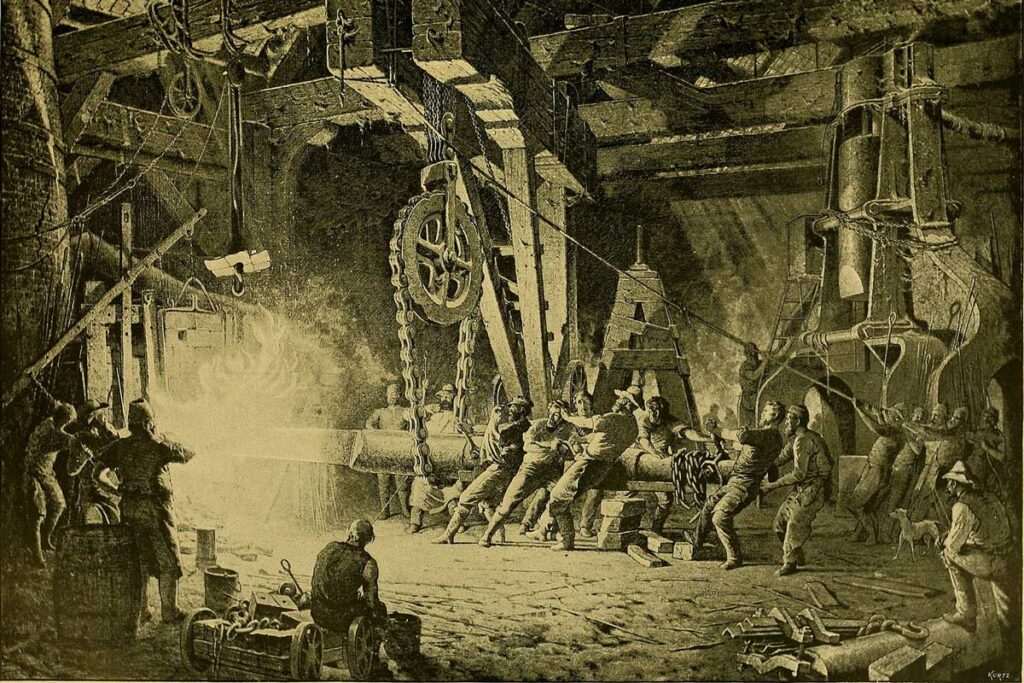

The Industrial Revolution that swept through Europe and America in the 19th century dramatically changed the landscape for many industries. The invention of the steam-powered engine had a significant impact on the forging industry. Steam was quickly used to power both large-scale drop hammers and presses. In this time, manipulators were also developed to hold larger forgings that were beyond man’s capabilities. Peddling, a metallurgical process discovered in Great Britain in the middle of the century, allowed forgers to heat metals higher than before. These advances resulted in more durable parts produced on a larger scale in a timelier manner. Another significant development in the 19th century was the ability to produce cheap steel on a large scale. Due to the increasing demands of steel for many industrial applications, pig iron, also known as crude iron, was created in Great Britain. Comprised of a high amount of carbon, crude iron is a high amount of carbon that cost a fraction of the steel that came before, and the mass production of the material was made possible by business owners that benefited from the creation of this type of steel. As a result, it quickly became a popular choice, especially in construction. The advancements made in forging during the Industrial Revolution made blacksmiths mostly a thing of the past. However, the Industrial Revolution set the foundation for the betterment of science and the development of new industries to require forged parts in the 20th century.

Forging in the 20th century

The 20th century saw rapid advancements in the automotive, aviation, and aerospace industries. As a result, technically advanced forgings were in demand, unlike anything seen before. From valves for cars and spaceships to engine components for aviation and aerospace, forgers and metallurgists continued to advance their processes to meet the needs of these industries. This was particularly true for aerospace applications, where new specialized alloys were created to meet the sector’s rigorous requirements.

Technological growth in the 20th century allowed metallurgy to flourish. With the invention of microscopes, scientists could finally see what the heating and forging processes do from a microstructural level. As a result, metallurgists were able to work with forging engineers and quality staff to perfect the various elements in forging – including how long to heat a particular piece of metal and at what temperature to ensure the best structural integrity of the finished part.

The 20th century also saw the widespread availability of electricity. With this came the invention of the electric-powered furnaces. Electric furnaces greatly impacted the forging industry as these furnaces allowed for precise heating in more efficient times.

Forged parts in the 20th century carried man across the land in cars and through the skies in airplanes and rockets. With such achievements made, one might ask how forging processes could continue to improve?

Forging in the 21st century

Just like forging in the previous centuries, forging at the end of the 21st century will look vastly different than it does today.

At the start of the 21st century, advancements in technology, machinery, and metallurgy drastically increased forging productions. Computers and engineering software have already significantly impacted the forging industry. Computer-controlled hydraulics and air-powered hammers and presses have improved forging production. And modern forging equipment, such as ring mills, allows forgers to produce parts with less stock needed to reduce costs for both the forger and the customers.

At the start of the 21st century, advancements in technology, machinery, and metallurgy drastically increased forging productions. Computers and engineering software have already significantly impacted the forging industry. Computer-controlled hydraulics and air-powered hammers and presses have improved forging production. And modern forging equipment, such as ring mills, allows forgers to produce parts with less stock needed to reduce costs for both the forger and the customers.

In more recent years, 3D additive manufacturing has become a popular option for some metal parts. This method creates 3D printed metal parts with powdered metals that are melted down and formed with lasers. This method can produce parts similar to forged parts but half the production time, and allowing customers and manufacturers the freedom to create new alloys for 3D printed metal parts. This would rid forgers from needing extensive inventories of alloys spread across many metal categories.

While the outlook of 3D additive manufacturing is positive, the industry is still relatively new and has many unknowns. Forging metal has an extensive history with thousands of years’ worth of insight for the method. Compared to 3D additive manufacturing, an industry with a 30-year history, it’s easy to see why some may be skeptical about this process.

3D printed metal parts are not the same as forged parts and does not compete against forging. There will always be a need for forged parts – one that 3D additive manufacturing cannot replace. These two methods could one day work in tandem for specific projects that would require metal parts with varied chemistries and microstructures.

Powdered metals will not be the only potential changes made to forging materials. High Entropy Alloys (HEAs) are a relatively new class of metals that forgers are not too familiar with at this time. HEAs are unique in that these alloys contain the same, usually large amounts of five or more elements. This radically differs from other metal categories, where one element is the base of an alloy while other elements make up a smaller amount of that alloy.

HEAs have many desirable characteristics and are considered advanced materials. As many industries will grow throughout the century, so could the need to forged HEAs parts. Forgers need to become familiar with the challenges of forging HEAs and be prepared to include HEAs in their inventory.

The forging equipment will continue to become more technologically advanced to improve and streamline the forging process. Through the use of thermomechanical processes, forging equipment could include advanced sensors. These sensors would provide microstructure and mechanical properties during the forging process. Forgers would get invaluable real-time insight into the parts they’re forging and could significantly reduce quality issues of parts.

Another way to streamline the forging process would be modifying the heating process. Heating parts are the biggest time constraint for forgers. Induction and rapid infrared heating could overtake traditional furnaces for heating parts. These methods would be a quicker way to heat parts and a more environmentally conscious way to heat parts.

While the basic concept of forging hasn’t changed in thousands of years, forging processes have been greatly enhanced over the centuries. Undoubtedly, forging processes will look different in the decades to com. However the forging industry will evolve, Weldaloy’s dedication to producing quality forged parts will be at the forefront of our business.