Weight Reduction Critical to Improved Jet Engine Fuel Efficiency

Replacing heavy metal parts in aeroengines with relatively lighter conventional Titanium alloys, titanium aluminides, and titanium containing high entropy alloys (HEAs) could reduce the weight of these parts by as much as 1,500 pounds – according to a talk presented at the International Materials Applications and Technology (IMAT) Conference, September 2022, by Dr. Ramachandra “Ram” Canumalla and Dr. T.V. Jayaraman.

The two researchers posit that substituting heavier, legacy nickel and steel alloys with advanced Ti alloys, titanium aluminides, and/or titanium containing lightweight HEAs will help aircraft to be more fuel efficient without compromising the structural integrity, saving up to14% in weight for an average aeroengine, and around 16% of the landing gear weight based on the open literature. Weight reduction is a critical factor for the aviation industry’s goal of carbon neutrality as each 1% reduction in an aircraft’s weight results in saving of 0.75% fuel.

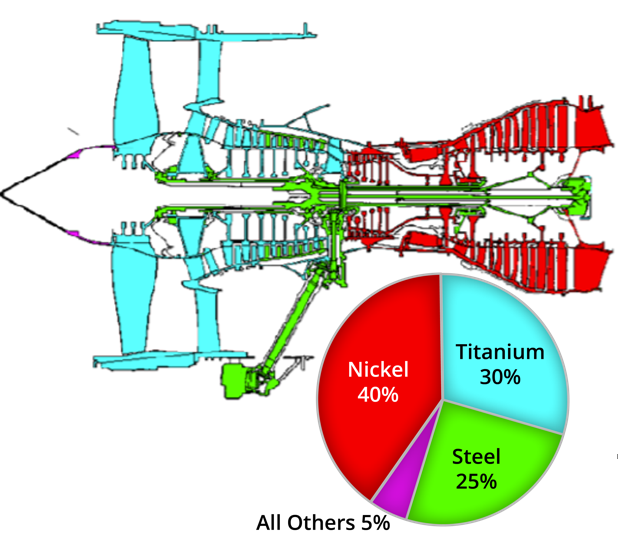

The use of titanium in the LEAP aeroengines has increased to 30% in 2018 from 0% in 1950. Canumalla and Jayaraman contend the proportion of titanium will continue to increase as developments of alloys, coatings, and manufacturing techniques, such as additive manufacturing, continue to advance.

The paper is timely, as the world’s airlines are attempting to achieve net zero emissions by 2050. Achieving net zero emissions is a huge challenge. To do this, the aviation industry must reduce its emissions by a cumulative of 21.2 gigatons of carbon by 2050. It is estimated ten billion people are expected to fly in 2050. That will require a reduction of at least 1.8 gigatons of carbon in that year alone.

According to the International Air Transport Association (IATA), the strategy is to abate as much CO2 as possible from in-sector solutions such as sustainable aviation fuels, new aircraft technology, more efficient operations and infrastructure, and the development of new zero-emissions energy sources such as electric and hydrogen power. Any emissions that cannot be eliminated at source will be eliminated through out-of-sector options such as carbon capture and storage and credible offsetting schemes.

Canumalla and Jayaraman presented the paper, “Conventional Ti Alloys for Aeroengines and Aircraft Landing Gear Beams: A Data Driven Selection and Future Directions,” again at Materials Science and Technology (MST) 2022, October 9-12, in Pittsburg, Pennsylvania. Sam Meyer, Weldaloy Lab Supervisor and Metallurgist, also presented.

Headed by Dr. Ram, Weldaloy Specialty Forgings engineering and metallurgy teams work with aerospace clients to find the best solutions for any forging challenge.

Dr. Ramachandra Canumalla, “Dr. Ram,” is VP and Chief Technology Officer at Weldaloy Specialty Forgings. Connect with Dr. Ram on LinkedIn

Dr. T.V. Jayaraman is a teaching professor at University of Michigan. Dr. Jayaraman’s bio