Advancing Forging Innovation with Precision and Reliability – Weldaloy Specialty Forgings

Advancing Forging Innovation with Precision and Reliability – Weldaloy Specialty Forgings

The demand for precision-engineered, critical components in the aerospace, power generation, and semiconductor industries drives Weldaloy Specialty Forgings. As a leader in forging innovation and excellence for over 78 years, Weldaloy is at the forefront of meeting these demands with top-tier talent, cutting-edge technology, and an unwavering commitment to quality.

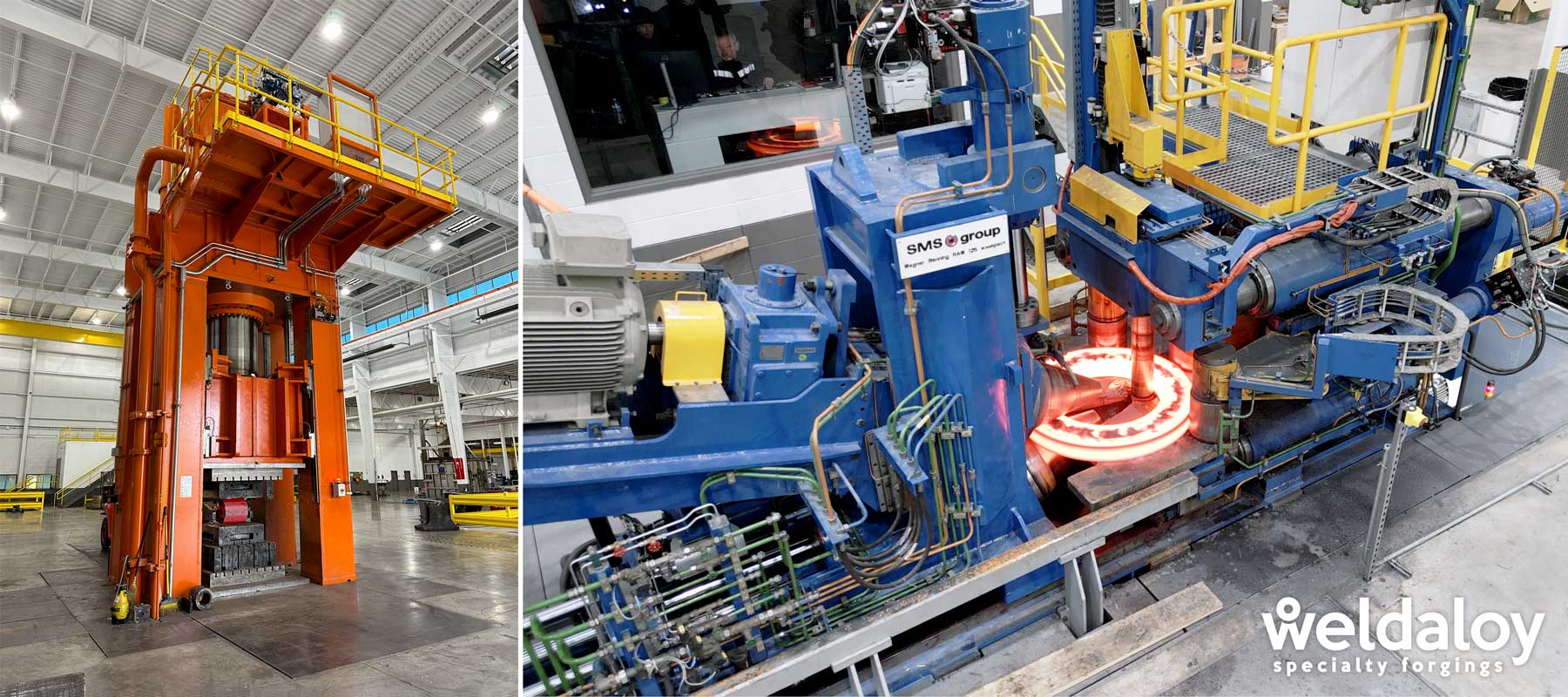

Pioneering Forging Technology with SMS Ring Mill

Weldaloy’s advanced forging operations feature a SMS Group Wagner Banning RAW 125 ecompact ring mill, the first of its kind in North America. This sophisticated equipment enables us to manufacture seamless rolled rings with diameters of up to 120+ inches. Designed to produce flawless, near net-shape rings in various profiles, the SMS ring mill has redefined efficiency and accuracy in forging, allowing us to meet exacting specifications for the space, aviation, defense, and power generation industries with ease.

We specialize in forging parts from titanium, super alloys, copper, stainless steel, and specialty non-ferrous alloys. With an extensive on-hand inventory of these metals, we ensure that we can meet customers’ needs swiftly and reliably.

Comprehensive Forging and Heat Treating Capabilities

In addition to producing seamless rolled rings with the SMS ring mill, Weldaloy offers open and semi-closed die forgings, including:

- Rectangles

- Stepped shafts

- Tubes

- Washers

- Bars

- Blocks

- Bushings

- Disks

- Forged rings

- Nozzles

We also provide heat-treating services such as solution treating, annealing, and precipitation hardening, ensuring each component meets stringent industry standards.

Our best-in-class integrated traceability system offers full documentation, transparency, and control over each step of the process.

In-House Engineering and R&D Expertise

Our in-house engineering and metallurgical teams work closely with clients to produce custom-forged parts to exact specifications, utilizing SolidWorks CAD/CAM and Forge Tansvalor simulation software. Our technical and production teams embrace challenging projects and eagerly assist with R&D initiatives, supporting minimum orders as low as one. Through continuous research and development, Weldaloy evaluates next-generation forging technologies and advances new processes, earning a reputation for delivering custom-engineered solutions that exceed industry expectations.

Certifications and Commitment to Quality

Quality forms the foundation of our operations. Our certifications underscore our commitment to meeting industry standards, including ISO 9001:2015, AS9100D, S1000, and ITAR compliance. Additionally, our ISO/IEC 17025-2017 accredited Metallurgical Laboratory enables precise testing and quality assurance, including non-destructive testing, room temperature tensile tests, and in-situ metallography.

To support quality and traceability, we operate a fully paperless PLEX ERP system, ensuring real-time data integration across all production stages. This system enhances operational efficiency and enables us to meet rigorous standards for consistency and precision.

With state-of-the-art forging equipment, seasoned expertise, and a clear focus on customer-driven innovation, Weldaloy Specialty Forgings is the trusted forging partner for industries where reliability and precision are paramount. Our ongoing investment in talent, advanced technologies, and process improvements provides dependable, innovative forging solutions for the space, aviation, defense, semiconductor, and power generation industries.